Linked Assemblies

In Fusion 360, linked components and assemblies are used to manage complex designs efficiently, allowing for reusable parts and streamlined workflows. Linked components enable modifications to be reflected across multiple instances, while assemblies provide a structured way to organize and manage interconnected parts.

Creating models by linking external components and assemblies is how Fusion 360 supports a Bottom-Up design approach.

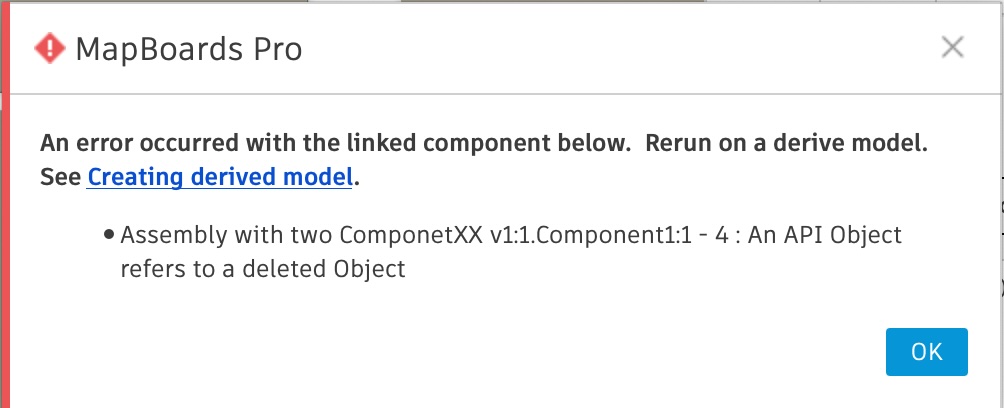

Models which include linked components and assemblies are supported. Rare but possible limitations exist. If encountered, you will be notified with a popup such as the following:

This can be corrected in one of three ways.

Break the one or more links in the model that MB is being run on then rerun MB (the easiest)

Or, derive a shadow model and run MB on that derived model. See Creating derived model for details.

Or, In the assembly or component being linked to, name all components and do NOT use Fusion’s automatic component names, such as Component**XX**. Instead, provide your own unique names.

Note

The model containing linked components or assemblies must be a saved model, and not an unsaved “Untitled” model, or the above error will occur.

Creating a derived model is quick and easy. If you choose to save that derived model, all changes in the source model will be reflected in the derived model, allowing you to rerun MB with changes to the original model.

Always ensure that you have removed maps created by MB from assemblies being linked into another model.

Remember to save any updates you make to the assembly and refresh the model where it is linked.